Supply Chain Management Review provides the latest information for business owners interested in improving their supply chain management. This magazine, based in the U.S., has been publishing for almost a decade, covering issues such as the role of information technology and the changing nature of business models. The publication offers an in-depth look at the industry, and is especially relevant to companies that manage a large supply chain.

Manufacturing is the last stage of supply chain management

Supply chain management is a complicated process that involves five key elements. They include planning, sourcing raw ingredients, manufacturing, delivery and return, and logistics. For companies to avoid costly bottlenecks, they need to be proficient at all five of these elements. Manufacturing is particularly important in perishable goods, as it requires timely delivery.

Reverse logistics

Reverse logistics management is vital to the bottom line of a company. This service allows companies to use existing infrastructure to reduce costs and increase efficiency. It can also help the reputation of a company by enabling companies to use sustainable business practices. However, reverse logistics is not without its challenges.

Flexible model

Businesses can have a flexible supply chain to meet their customers' needs when they are high or low. It is based on part segmentation and accurate stocking algorithms. Flexible planning includes automation on factory floors. Staples for writing utensils is one example. They anticipate a spike in demand during back to school season and stock up throughout the year.

Agile model

Organizations can use an Agile model to review their supply chain management. This will allow them to make major changes and ensure that they are responsive to any changes. Although delays and losses can occur due to the loss of significant manufacturing partners or logistical blocks, an agile supply system can quickly overcome these obstacles. It also gives visibility to supply chain stakeholders, which allows them to improve the efficiency of their process. It allows organizations to outsource particular supply chain segments, leading to lower costs. It also helps businesses anticipate shortages and reduce overstock inventories.

Model of fast-chain

A fast supply chain model emphasizes speed and responsiveness. It is ideal for companies with multiple product lines that compete for the very same customers. This model is known for efficient inventory management and maximising the use of production equipment. It is best suited for businesses that produce trendy items with short life cycles. Businesses that are looking to bring products to market quickly will also benefit from this model.

Supply chain management: Ethics

Companies should be mindful of ethics in supply-chain management, which has significant implications for their business performance as well as the bottom line. Supply chain companies face many problems, not just those facing factories and workers. To help ensure ethical supply chains, organizations are undertaking a number of initiatives.

FAQ

What skills are required to be a production manager?

A production planner must be organized, flexible, and able multitask to succeed. Effective communication with clients and colleagues is essential.

What are the goods of logistics?

Logistics refers to all activities that involve moving goods from A to B.

These include all aspects related to transport such as packaging, loading and transporting, storing, transporting, unloading and warehousing inventory management, customer service. Distribution, returns, recycling are some of the options.

Logisticians make sure that the right product arrives at the right place at the correct time and in safe conditions. They help companies manage their supply chain efficiency by providing information on demand forecasts, stock levels, production schedules, and availability of raw materials.

They coordinate with vendors and suppliers, keep track of shipments, monitor quality standards and perform inventory and order replenishment.

How can I find out more about manufacturing?

Practical experience is the best way of learning about manufacturing. You can also read educational videos or take classes if this isn't possible.

What are the 4 types manufacturing?

Manufacturing is the process of transforming raw materials into useful products using machines and processes. Manufacturing can include many activities such as designing and building, testing, packaging shipping, selling, servicing, and other related activities.

What does it take to run a logistics business?

You need to have a lot of knowledge and skills to manage a successful logistic business. You must have good communication skills to interact effectively with your clients and suppliers. You will need to know how to interpret data and draw conclusions. You will need to be able handle pressure well and work in stressful situations. You need to be innovative and creative to come up with new ways to increase efficiency. You need to have strong leadership qualities to motivate team members and direct them towards achieving organizational goals.

You must be organized to meet tight deadlines.

What is the distinction between Production Planning or Scheduling?

Production Planning (PP) refers to the process of determining how much production is needed at any given moment. Forecasting and identifying production capacity are two key elements to this process.

Scheduling is the process that assigns dates to tasks so they can get completed within a given timeframe.

Are there ways to automate parts of manufacturing?

Yes! Yes. The wheel was invented by the Egyptians thousands of years ago. To help us build assembly lines, we now have robots.

There are many uses of robotics today in manufacturing. They include:

-

Robots for assembly line

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Manufacturing can also be automated in many other ways. 3D printing is a way to make custom products quickly and without waiting weeks or months for them to be manufactured.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

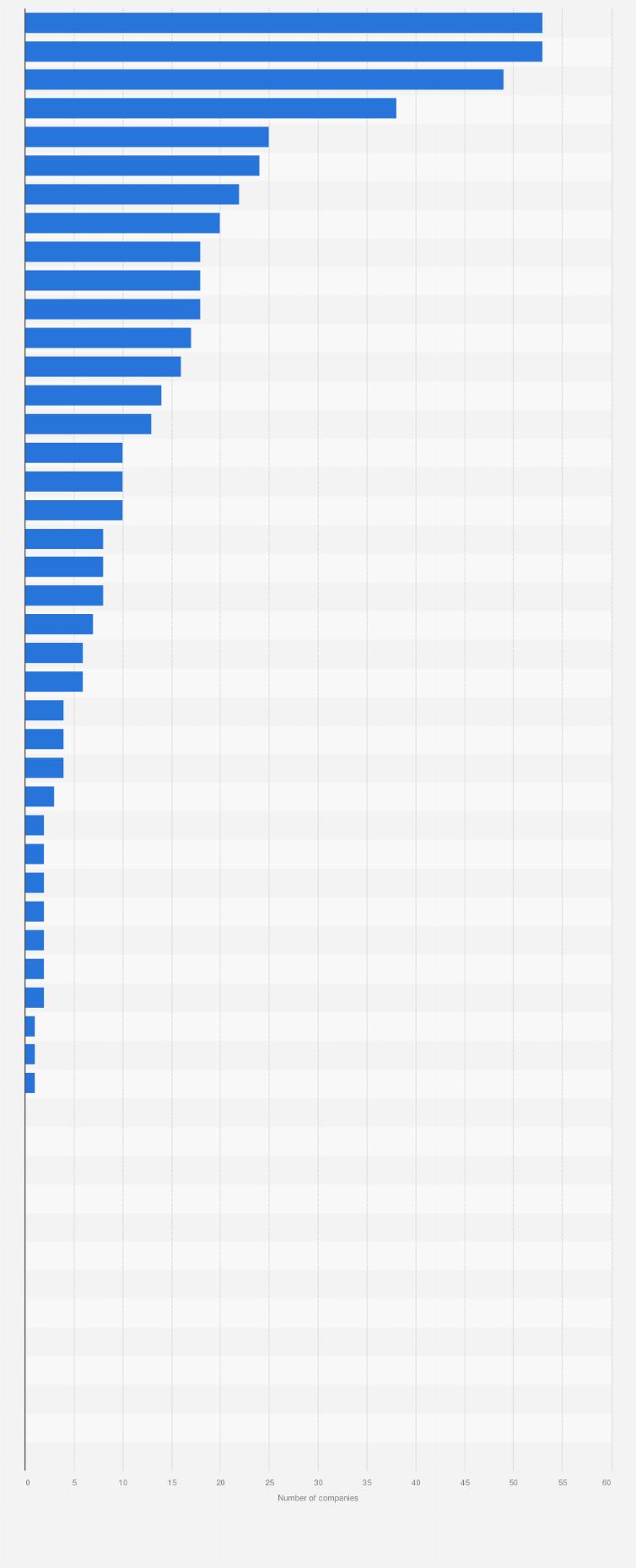

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

External Links

How To

Six Sigma and Manufacturing

Six Sigma is defined by "the application SPC (statistical process control) techniques to achieve continuous improvements." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. Six Sigma's core idea is to improve the quality of processes by standardizing and eliminating defects. In recent years, many companies have adopted this method because they believe there is no such thing as perfect products or services. Six Sigma aims to reduce variation in the production's mean value. If you take a sample and compare it with the average, you will be able to determine how much of the production process is different from the norm. If there is a significant deviation from the norm, you will know that something needs to change.

Understanding how your business' variability is a key step towards Six Sigma implementation is the first. Once you have a good understanding of the basics, you can identify potential sources of variation. Also, you will need to identify the sources of variation. Random variations are caused when people make mistakes. While systematic variations are caused outside of the process, they can occur. You could consider random variations if some widgets fall off the assembly lines. You might notice that your widgets always fall apart at the same place every time you put them together.

After identifying the problem areas, you will need to devise solutions. The solution could involve changing how you do things, or redesigning your entire process. To verify that the changes have worked, you need to test them again. If they fail, you can go back to the drawing board to come up with a different plan.