Jobs in wind turbine manufacturing

Wind turbine manufacturing jobs include a variety of tasks that require specialized knowledge and skills. These jobs could include blade epoxies or tower assembly. Some wind turbine manufacturing companies also contract with third-party suppliers to manufacture various components. Wind turbine parts are very large and require to be transported quickly. Teams of logisticians or rail freight drivers are needed by companies to complete this task.

Most jobs in the manufacturing of wind turbines require a bachelor's or master's degree. Wind turbine manufacturing jobs require both engineering and environmental engineering specializations. Entry-level engineers will need advanced computer skills and experience, in addition to a degree. They work closely with more experienced staff to ensure quality control. They may also be assigned more complex projects.

Processes involved in wind turbine manufacturing

The main part of a windturbine is its blades. Each blade has two faces connected by integral shear Webs. The blades are supported by a box spar and shell fairings. These structures are rigid enough to resist edgewise and flapwise loads. The spar resists edgewise bends caused by wind pressure or gravitational forces. These forces are resistant to the blades.

Blades can be made from many different materials. Aluminum and lightweight woods are also options. While fiberglass is the most commonly used material for commercial windturbine blades, it can be made from other materials as well. The blades are then covered in airtight foil and connected to tubes that pump resin.

Competitors of the wind turbine manufacturing industry

Although Chinese manufacturers are a rising force in global wind industry, it is not yet the dominant one. Chinese turbine producers have had trouble eclipsing the incumbent manufacturers in developed countries. Despite this, they may be poised to eventually increase their overseas activities if they invest in local manufacturing capabilities.

Although large turbine manufacturers are increasingly outsourcing components, many individuals are still choosing to build the parts themselves. This comes with both benefits and disadvantages. Vestas in Pueblo (Colorado) has adopted this strategy and now manufactures wind turbine towers to support third-party US projects. This agreement allows the tower factory to use up 25 percent of its manufacturing capacity and supports 100 jobs in the local area. Quality control is a problem with this approach. In the past, outsourced components have experienced failures such as blade cracking and gearbox failures. Many offshore foundations are even made from poor quality steel.

Health and safety concerns in wind turbine manufacturing

Health and safety is one of the most important issues in wind turbine manufacturing. Many hazards are present that can cause long-term injury or even death for workers. There are many things you can do to reduce the risk. These tips will help you keep your employees safe at work in a windturbine manufacturing plant.

Exposure to dangerous gases, vapors and dust is one of the greatest hazards in the manufacturing of wind turbine blades. To reduce the risk of exposure, workers should wear respirators and must be properly trained in using them. This is possible only with proper training. Ear protection is also a critical factor.

FAQ

How can we increase manufacturing efficiency?

First, we need to identify which factors are most critical in affecting production times. We must then find ways that we can improve these factors. If you don’t know how to start, look at which factors have the greatest impact upon production time. Once you've identified them all, find solutions to each one.

What is the distinction between Production Planning or Scheduling?

Production Planning (PP), also known as forecasting and identifying production capacities, is the process that determines what product needs to be produced at any particular time. This is accomplished by forecasting the demand and identifying production resources.

Scheduling refers to the process of allocating specific dates to tasks in order that they can be completed within a specified timeframe.

What can I do to learn more about manufacturing?

You can learn the most about manufacturing by getting involved in it. But if that is not possible you can always read books and watch educational videos.

What are the differences between these four types?

Manufacturing is the process by which raw materials are transformed into useful products through machines and processes. It includes many different activities like designing, building and testing, packaging, shipping and selling, as well as servicing.

What does manufacturing industry mean?

Manufacturing Industries are companies that manufacture products. Consumers are the people who purchase these products. These companies use various processes such as production, distribution, retailing, management, etc., to fulfill this purpose. They produce goods from raw materials by using machines and other machinery. This covers all types of manufactured goods including clothing, food, building supplies and furniture, as well as electronics, tools, machinery, vehicles and pharmaceuticals.

Are there any Manufacturing Processes that we should know before we can learn about Logistics?

No. You don't have to know about manufacturing processes before learning about logistics. However, knowing about manufacturing processes will definitely give you a better understanding of how logistics works.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

External Links

How To

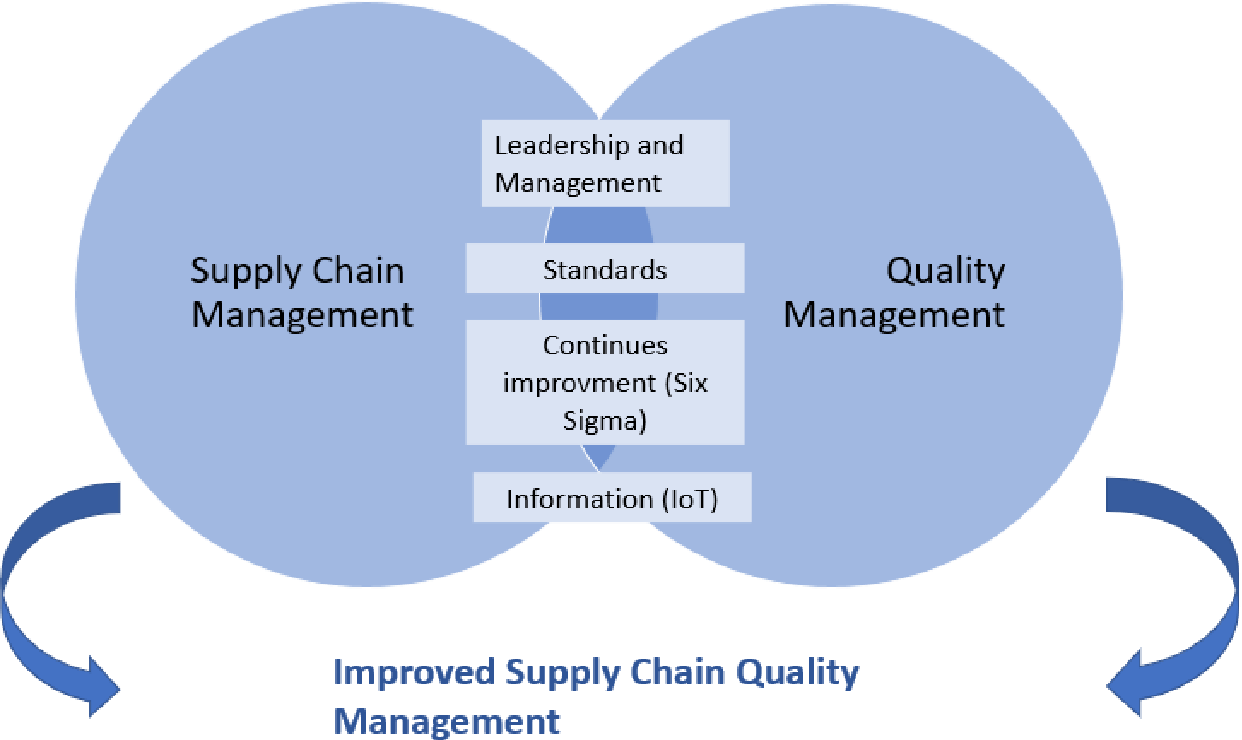

Six Sigma and Manufacturing

Six Sigma is "the application statistical process control (SPC), techniques for continuous improvement." Motorola's Quality Improvement Department created Six Sigma at their Tokyo plant, Japan in 1986. Six Sigma's basic concept is to improve quality and eliminate defects through standardization. This method has been adopted by many companies in recent years as they believe there are no perfect products or services. Six Sigma seeks to reduce variation between the mean production value. This means that you can take a sample from your product and then compare its performance to the average to find out how often the process differs from the norm. If you notice a large deviation, then it is time to fix it.

The first step toward implementing Six Sigma is understanding how variability works in your business. Once you have this understanding, you will need to identify sources and causes of variation. It is important to identify whether the variations are random or systemic. Random variations occur when people do mistakes. Symmetrical variations are caused due to factors beyond the process. Random variations would include, for example, the failure of some widgets to fall from the assembly line. It would be considered a systematic problem if every widget that you build falls apart at the same location each time.

Once you've identified the problem areas you need to find solutions. This could mean changing your approach or redesigning the entire process. To verify that the changes have worked, you need to test them again. If they don’t work, you’ll need to go back and rework the plan.