Industrial engineers are able to use math and science to increase efficiency in production. They can identify and fix flaws in systems, and create solutions that increase productivity and performance. They are also capable of creating new processes that reduce the use of resources. If you enjoy working with others and are independent, this career is appealing. It also offers the chance to advance in their careers and transition into management positions.

Industrial engineers may work in a variety of industries. Some of their duties include working in hazardous materials, or at very high temperatures. They also may be required to travel to different locations to perform their work. They may also be required to communicate via email, telephone and face-to–face to resolve problems. They should be able to comprehend workplace safety laws.

Industrial engineers are highly valued because they are able to come up with creative solutions to problems. Industrial engineers enjoy solving problems that increase efficiency. You might find them designing assembly lines to lower costs or improve production. Sometimes, they may have to work overtime in order to meet deadlines. They might have the opportunity to collaborate with other engineers to create new production processes.

The expectations of industrial engineers are to be able to communicate effectively with others, and to listen and understand the opinions of others. They must also be able and willing to collaborate with their supervisors and coworkers. They should also be able use their critical thinking skills and identify alternative solutions to problems. They are also able predict the impact of changes and take steps to increase their chances.

Depending upon their job duties, industrial engineer may have to work in noisy areas, work long hours and travel to different places. Sometimes, they may have trouble balancing work and family life. While this can be difficult, it is possible for them to adjust to their work.

Most industrial engineers have a bachelor's. You can then go on to earn a master's, or doctorate. This process can take anywhere from two years to seven years. It is crucial to choose the right degree program for you. Many higher education institutions offer online degrees in industrial engineering. These programs allow students to finish their studies quickly and without paying high tuition fees. They also offer flexibility for students in their study time.

Industrial engineers may find joining professional organizations like the Institute of Industrial and Systems Engineers helpful. This organization organizes conferences and publishes white papers. It also supports industrial engineers. The organization also offers fellowships to recent graduates. They can also take advantage of certifications and MOOCs. They may also participate in fellowships from the American Society for Engineering Education.

Government agencies can also offer employment for industrial engineers. They may be required to obtain licensure. Some large companies may provide formal training. These employers appreciate the experience industrial engineers have.

FAQ

What jobs are available in logistics?

Logistics can offer many different jobs. Here are some:

-

Warehouse workers: They load and unload trucks, pallets, and other cargo.

-

Transportation drivers: They drive trucks and trailers and deliver goods and make pick-ups.

-

Freight handlers: They sort and package freight in warehouses.

-

Inventory managers – They manage the inventory in warehouses.

-

Sales reps are people who sell products to customers.

-

Logistics coordinators – They plan and coordinate logistics operations.

-

Purchasing agents: They are responsible for purchasing goods and services to support company operations.

-

Customer service agents - They answer phone calls and respond to emails.

-

Shipping clerks - They process shipping orders and issue bills.

-

Order fillers: They fill orders based off what has been ordered and shipped.

-

Quality control inspectors are responsible for inspecting incoming and outgoing products looking for defects.

-

Others - There is a variety of other jobs in logistics. These include transportation supervisors and cargo specialists.

How can manufacturing excess production be decreased?

In order to reduce excess production, you need to develop better inventory management methods. This would reduce the amount of time spent on unnecessary activities such as purchasing, storing, and maintaining excess stock. We could use these resources to do other productive tasks.

One way to do this is to adopt a Kanban system. A Kanban board, a visual display to show the progress of work, is called a Kanban board. A Kanban system allows work items to move through several states before reaching their final destination. Each state has a different priority level.

As an example, if work is progressing from one stage of the process to another, then the current task is complete and can be transferred to the next. It is possible to keep a task in the beginning stages until it gets to the end.

This allows for work to continue moving forward, while also ensuring that there is no work left behind. Managers can view the Kanban board to see how much work they have done. This information allows managers to adjust their workflow based off real-time data.

Lean manufacturing can also be used to reduce inventory levels. Lean manufacturing works to eliminate waste throughout every stage of the production chain. Any product that isn't adding value can be considered waste. There are several types of waste that you might encounter:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Excess materials

These ideas can help manufacturers improve efficiency and reduce costs.

Is automation necessary in manufacturing?

Not only are service providers and manufacturers important, but so is automation. Automation allows them to deliver services quicker and more efficiently. They can also reduce their costs by reducing human error and improving productivity.

What is the best way to learn about manufacturing?

The best way to learn about manufacturing is through hands-on experience. But if that is not possible you can always read books and watch educational videos.

How does a Production Planner differ from a Project Manager?

The primary difference between a producer planner and a manager of a project is that the manager usually plans and organizes the whole project, while a production planner is only involved in the planning stage.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

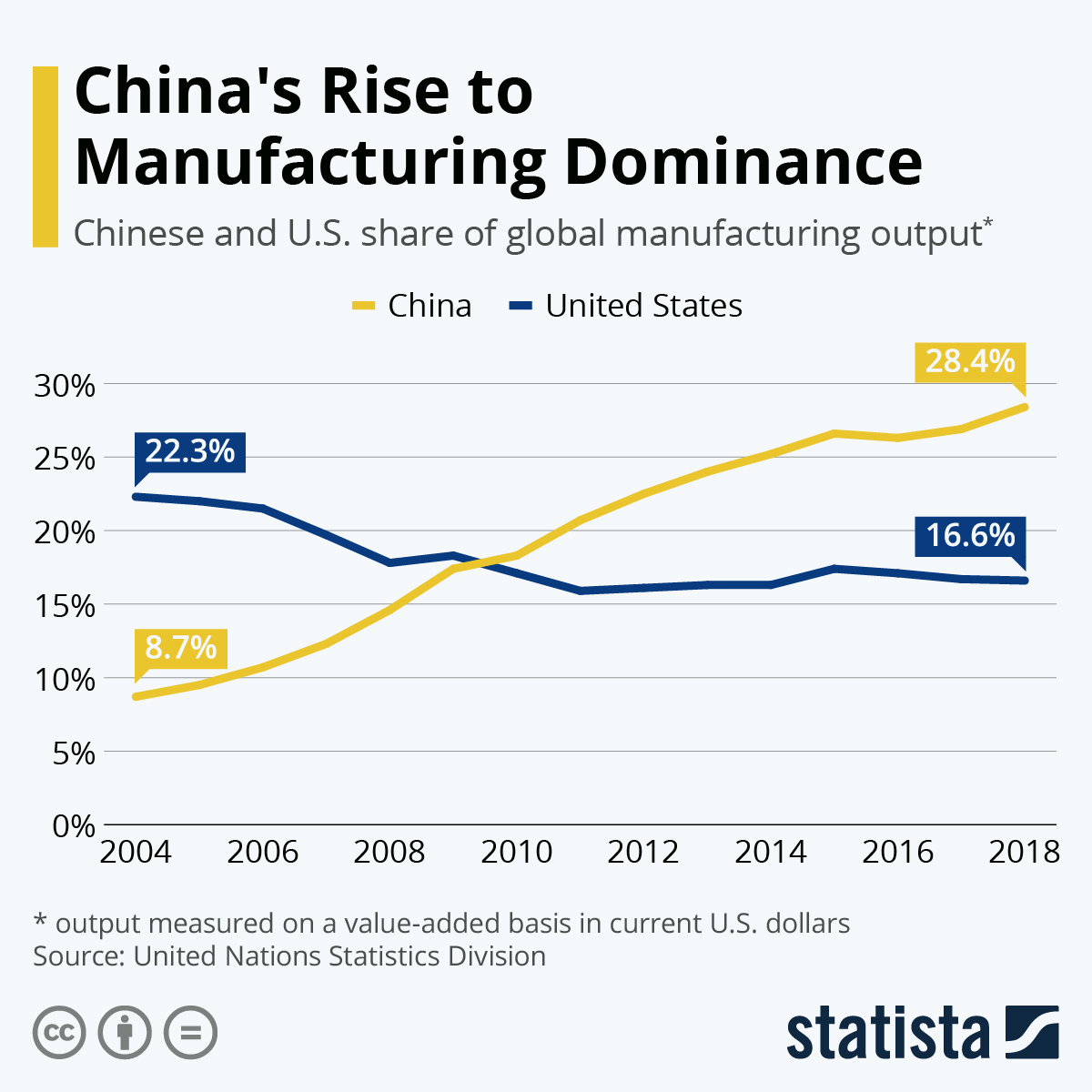

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

How to Use 5S for Increasing Productivity in Manufacturing

5S stands to stand for "Sort", “Set In Order", “Standardize", and "Store". Toyota Motor Corporation was the first to develop the 5S approach in 1954. It improves the work environment and helps companies to achieve greater efficiency.

This method aims to standardize production processes so that they are repeatable, measurable and predictable. Cleaning, sorting and packing are all done daily. This knowledge allows workers to be more efficient in their work because they are aware of what to expect.

There are five steps that you need to follow in order to implement 5S. Each step involves a different action which leads to increased efficiency. For example, when you sort things, you make them easy to find later. You arrange items by placing them in an order. Then, after you separate your inventory into groups, you store those groups in containers that are easy to access. Make sure everything is correctly labeled when you label your containers.

Employees need to reflect on how they do their jobs. Employees need to understand the reasons they do certain jobs and determine if there is a better way. To implement the 5S system, employees must acquire new skills and techniques.

In addition to increasing efficiency, the 5S method also improves morale and teamwork among employees. Once they start to notice improvements, they are motivated to keep working towards their goal of increasing efficiency.