The job description for an industrial engineer includes the science and art of time-and motion. This engineer examines the interaction of people with machines, systems and energy. Additionally, industrial engineers need to be familiar with economics and mechanical design. They also need a basic understanding of algorithms. Industrial engineers have many requirements and the job description can vary from one employer to the next. You can apply for an engineering job if you hold a bachelor's degree.

Work environment

For an industrial engineer, these are essential skills. Industrial engineers combine previous skills with the demands of their current job. Industrial engineers manage moderately complex projects in industrial engineering and perform statistical analyses to improve production flow and standard time. Additionally, they manage strategy deployment through Value Stream Mapping (or Bottleneck Analysis). They may also work with multidisciplinary teams to resolve several problems at a time.

Education

Relevant work experience will increase your chances to land a job in the industrial engineering field. Some degree programs require you to work as an intern in order for you to gain relevant experience. In some cases, employers will hire even after graduation. Consider obtaining specialized certifications in industrial engineering. A professional certification not only shows that you have the necessary skills, but it also shows that you are dedicated to your career. These are the top ways to get started on your quest for an industrial engineer job.

Salary

The average annual salary for an industrial engineer job in the United States is $81,700. This job's salary depends on experience and education, as well the market, industry size and market. The duties of an industrial engineer include Packaging Engineering. This position requires long hours of standing, and may also involve other duties like working with a team to develop new products. An industrial engineer must be able to communicate well and analyze data.

Certifications

You may improve your job performance by getting a certificate in industrial engineering. Many industrial engineer certifications require intense study, courses, examinations, and testing. These certifications can be a huge benefit to employers. It is also much easier to earn them. In the past, industrial engineers had to travel to local colleges or other institutions to earn the required certifications. But with online training, earning the certification is much faster and easier.

Myers Briggs personality type

Knowing your Myers Briggs personality type could help you find the job that best suits your interests and skills. This test, also known as the MBTI, measures four types: Introverted-Intuitive-Thinking, Sensing/Intuitive, Thinking/Feeling, and Perceived/Judged. Employers and employees both find it useful.

FAQ

What is production planning?

Production Planning refers to the development of a plan for every aspect of production. This document aims to ensure that everything is planned and ready when you are ready to shoot. It should also provide information about how best to produce the best results while on set. This includes shooting schedules, locations, cast lists, crew details, and equipment requirements.

First, you need to plan what you want to film. You may have already decided where you would like to shoot, or maybe there are specific locations or sets that you want to use. Once you have identified your locations and scenes, you can start working out which elements you require for each scene. You might decide you need a car, but not sure what make or model. You could look online for cars to see what options are available, and then narrow down your choices by selecting between different makes or models.

Once you have found the right car, you can start thinking about extras. You might need to have people in the front seats. Or perhaps you need someone walking around the back of the car? Perhaps you would like to change the interior colour from black to white. These questions will help to determine the style and feel of your car. Also, think about what kind of shots you would like to capture. Do you want to film close-ups, or wider angles? Maybe you want the engine or the steering wheels to be shown. This will allow you to determine the type of car you want.

Once you have determined all of the above, you can move on to creating a schedule. A schedule will tell you when you need to start shooting and when you need to finish. The schedule will show you when to get there, what time to leave, and when to return home. It will help everyone know exactly what they have to do and when. You can also make sure to book extra staff in advance if you have to hire them. You don't want to hire someone who won't show up because he didn't know.

Your schedule will also have to be adjusted to reflect the number of days required to film. Some projects can be completed in a matter of days or weeks. Others may take several days. While creating your schedule, it is important to remember whether you will require more than one shot per day. Shooting multiple takes over the same location will increase costs and take longer to complete. It's better to be safe than sorry and shoot less takes if you're not certain whether you need more takes.

Budgeting is another crucial aspect of production plan. As it will allow you and your team to work within your financial means, setting a realistic budget is crucial. If you have to reduce your budget due to unexpected circumstances, you can always lower it later. You shouldn't underestimate the amount you'll spend. If you underestimate the cost of something, you will have less money left after paying for other items.

Production planning is a complicated process. But once you understand how everything works together, it becomes much easier to plan future project.

What are the goods of logistics?

Logistics are the activities involved in moving goods from point A to point B.

They encompass all aspects transport, including packaging and loading, transporting, storage, unloading.

Logisticians ensure that the product is delivered to the correct place, at the right time, and under safe conditions. They help companies manage their supply chain efficiency by providing information on demand forecasts, stock levels, production schedules, and availability of raw materials.

They coordinate with vendors and suppliers, keep track of shipments, monitor quality standards and perform inventory and order replenishment.

How can I find out more about manufacturing?

Practical experience is the best way of learning about manufacturing. But if that is not possible you can always read books and watch educational videos.

Can certain manufacturing steps be automated?

Yes! Yes. Automation has been around since ancient time. The wheel was invented by the Egyptians thousands of years ago. We now use robots to help us with assembly lines.

Actually, robotics can be used in manufacturing for many purposes. These include:

-

Line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

There are many other examples of how manufacturing could benefit from automation. For example, 3D printing allows us to make custom products without having to wait for weeks or months to get them manufactured.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to Use Lean Manufacturing in the Production of Goods

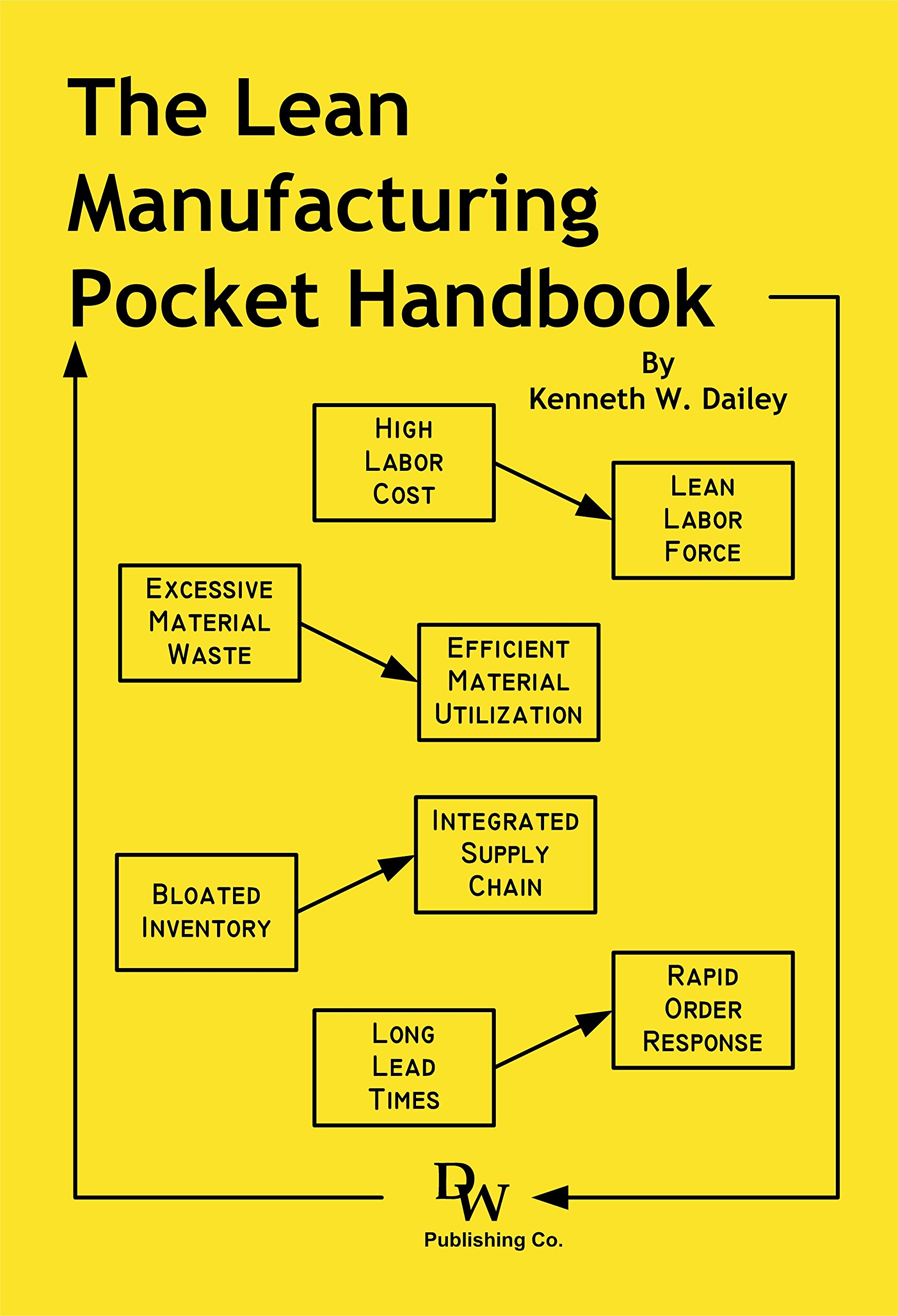

Lean manufacturing refers to a method of managing that seeks to improve efficiency and decrease waste. It was first developed in Japan in the 1970s/80s by Taiichi Ahno, who was awarded the Toyota Production System (TPS), award from KanjiToyoda, the founder of TPS. The first book published on lean manufacturing was titled "The Machine That Changed the World" written by Michael L. Watkins and published in 1990.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It emphasizes the elimination and minimization of waste in the value stream. Just-in-time (JIT), zero defect (TPM), and 5S are all examples of lean manufacturing. Lean manufacturing seeks to eliminate non-value added activities, such as inspection, work, waiting, and rework.

Lean manufacturing improves product quality and costs. It also helps companies reach their goals quicker and decreases employee turnover. Lean manufacturing is a great way to manage the entire value chain including customers, suppliers, distributors and retailers as well as employees. Lean manufacturing can be found in many industries. Toyota's philosophy is a great example of this. It has helped to create success in automobiles as well electronics, appliances and healthcare.

Lean manufacturing includes five basic principles:

-

Define Value- Identify the added value your company brings to society. What makes you stand out from your competitors?

-

Reduce Waste – Eliminate all activities that don't add value throughout the supply chain.

-

Create Flow - Make sure work runs smoothly without interruptions.

-

Standardize & simplify - Make processes consistent and repeatable.

-

Build Relationships- Develop personal relationships with both internal as well as external stakeholders.

Lean manufacturing is not a new concept, but it has been gaining popularity over the last few years due to a renewed interest in the economy following the global financial crisis of 2008. To increase their competitiveness, many businesses have turned to lean manufacturing. According to some economists, lean manufacturing could be a significant factor in the economic recovery.

With many benefits, lean manufacturing is becoming more common in the automotive industry. These include improved customer satisfaction, reduced inventory levels, lower operating costs, increased productivity, and better overall safety.

Lean manufacturing can be applied to almost every aspect of an organization. This is because it ensures efficiency and effectiveness in all stages of the value chain.

There are three main types in lean manufacturing

-

Just-in-Time Manufacturing: Also known as "pull systems", this type of lean manufacturing uses just-in-time manufacturing (JIT). JIT stands for a system where components are assembled on the spot rather than being made in advance. This approach reduces lead time, increases availability and reduces inventory.

-

Zero Defects Manufacturing (ZDM): ZDM focuses on ensuring that no defective units leave the manufacturing facility. If a part is required to be repaired on the assembly line, it should not be scrapped. This is also true for finished products that require minor repairs before shipping.

-

Continuous Improvement (CI),: Continuous improvement aims improve the efficiency and effectiveness of operations by continuously identifying issues and making changes to reduce waste. Continuous Improvement (CI) involves continuous improvement in processes, people, tools, and infrastructure.