Manufacturing Day celebrates the contributions of the United States' modern manufacturing sector. This celebration occurs on the first Friday each month in October. This celebration is also an opportunity to encourage the next generation to pursue careers in manufacturing.

Manufacturing Day can be celebrated by many different ways. These events could be organized by schools and corporations as well as other organizations. Some events include presentations and factory tours. Others may provide virtual content about local manufacturers. These events often include hands-on activities, which can be useful for students.

The economic vitality of manufacturers is essential. Every dollar spent in manufacturing creates $2.79 to the economy. It is also important to note that manufacturing is an industry that requires a skilled workforce. The average cost of manufacturing is 2.5 times that of large companies.

Manufacturing Day was supported in part by numerous federal agencies such as the Department of Education (Advanced Manufacturing Office), the National Association of Manufacturers (NAM) and the Department of Education. This day provides an opportunity for manufacturers and educators to meet with local schools, communities, and businesses. These agencies can help you plan events. These agencies also support official proclamations, factory tours, and other related activities.

Some companies organize special seminars to inspire youth to pursue a career in manufacturing. These initiatives are also supported by The Manufacturing Institute, a National Association of Manufacturers workforce development partner. The Institute provides manufacturers with resources to help them address industry challenges and build a stronger community. The Institute offers support to veterans and women working in manufacturing.

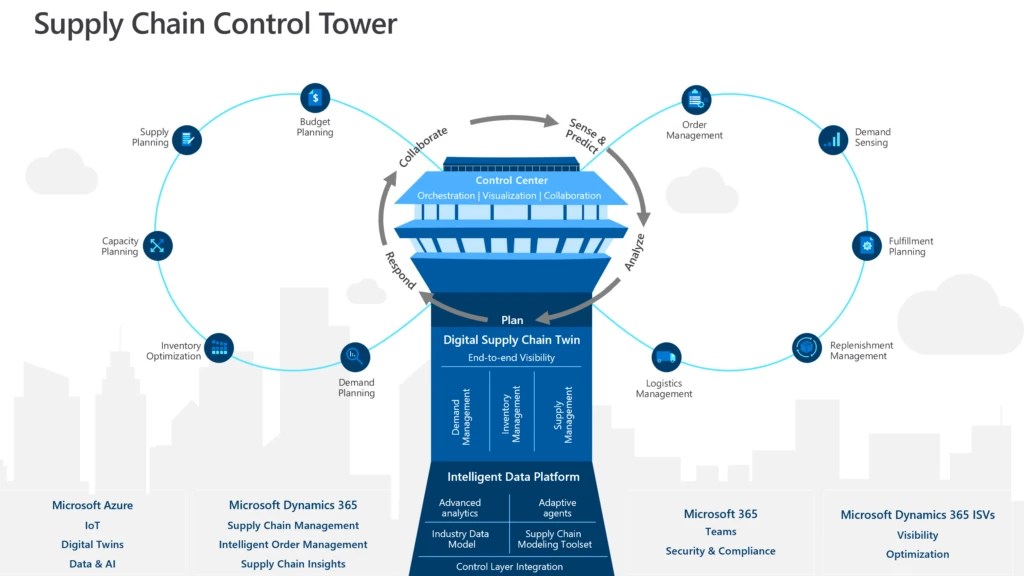

The Biden-Harris administration works to revive the manufacturing sector. They are focusing on building strong supply networks and investing in R&D.

AIM's 3D Virtual Reality Headsets for Students are available to them to allow them to experience advanced manufacturing occupations. AIM will also work with schools in the Detroit area to bring students to factories that manufacture products. The virtual tours will allow students to get a glimpse into the manufacturing processes. Students will have the opportunity to participate in virtual panels.

Manufacturing Day celebrations include the National Strategy for Advanced Manufacturing. The Strategy encourages manufacturing companies to take part in education opportunities and training programs that benefit their local economy. In addition, manufacturers can organize job fairs to help people find opportunities in manufacturing.

Participating in an event hosted by the Manufacturing Institute will allow students to learn more about manufacturing careers. This event is also intended to promote inclusion and diversity in manufacturing. Some events include testimonials by people working in manufacturing.

The National Association of Manufacturers and Fabricators and Manufacturers Association will host educational events that showcase the importance of the manufacturing industry. These events are a great way for students to learn about manufacturing's importance to the economy as well as explore the many career opportunities in this industry.

FAQ

Is there anything we should know about Manufacturing Processes prior to learning about Logistics.

No. You don't have to know about manufacturing processes before learning about logistics. However, knowing about manufacturing processes will definitely give you a better understanding of how logistics works.

How can manufacturing efficiency improved?

The first step is to determine the key factors that impact production time. Next, we must find ways to improve those factors. You can start by identifying the most important factors that impact production time. Once you have identified the factors, then try to find solutions.

What is production planning?

Production Planning refers to the development of a plan for every aspect of production. This document is designed to make sure everything is ready for when you're ready to shoot. This document should include information about how to achieve the best results on-set. This information includes locations, crew details and equipment requirements.

It is important to first outline the type of film you would like to make. You may already know where you want the film to be shot, or perhaps you have specific locations and sets you wish to use. Once you have identified the scenes and locations, you can start to determine which elements are required for each scene. You might decide you need a car, but not sure what make or model. This is where you can look up car models online and narrow down your options by choosing from different makes and models.

After you have chosen the right car, you will be able to begin thinking about accessories. Are you looking for people to sit in the front seats? Or perhaps you need someone walking around the back of the car? Maybe you'd like to change the interior from black to a white color. These questions can help you decide the right look for your car. It is also worth considering the types of shots that you wish to take. Will you be filming close-ups or wide angles? Maybe you want to show your engine or the steering wheel. These details will help identify the exact car you wish to film.

Once you have made all the necessary decisions, you can start to create a schedule. The schedule will show you when to begin shooting and when to stop. A schedule for each day will detail when you should arrive at the location and when you need leave. Everyone will know what they need and when. It is possible to make arrangements in advance for additional staff if you are looking to hire. It is not worth hiring someone who won’t show up because you didn’t tell him.

It is important to calculate the amount of filming days when you are creating your schedule. Some projects may only take a couple of days, while others could last for weeks. When creating your schedule, be aware of whether you need more shots per day. Multiplying takes in the same area will result both in increased costs and a longer time. It's better to be safe than sorry and shoot less takes if you're not certain whether you need more takes.

Another important aspect of production planning is setting budgets. A realistic budget will help you work within your means. Keep in mind that you can always reduce your budget if you face unexpected difficulties. However, it is important not to overestimate the amount that you will spend. If you underestimate the cost of something, you will have less money left after paying for other items.

Production planning is a very detailed process, but once you understand how everything works together, it becomes easier to plan future projects.

Statistics

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

How to use 5S to increase Productivity in Manufacturing

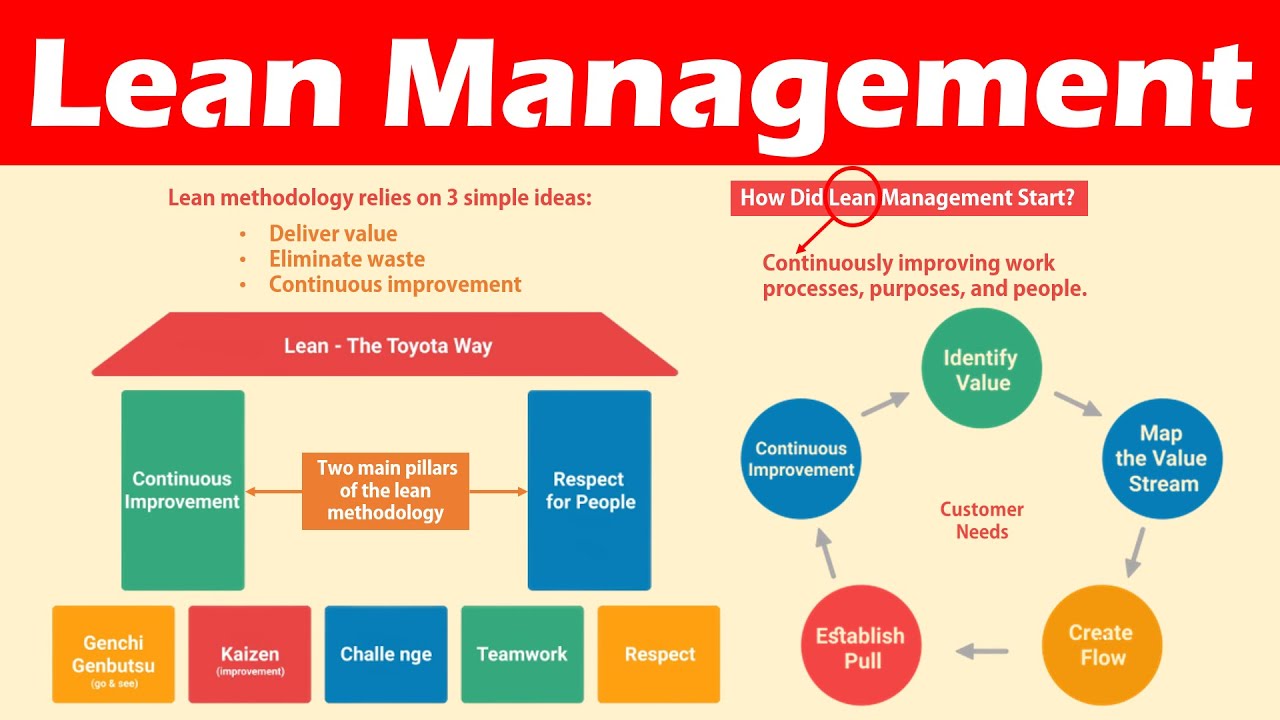

5S stands for "Sort", "Set In Order", "Standardize", "Separate" and "Store". Toyota Motor Corporation was the first to develop the 5S approach in 1954. It helps companies achieve higher levels of efficiency by improving their work environment.

This method has the basic goal of standardizing production processes to make them repeatable. This means that every day tasks such cleaning, sorting/storing, packing, and labeling can be performed. These actions allow workers to perform their job more efficiently, knowing what to expect.

There are five steps to implementing 5S, including Sort, Set In Order, Standardize, Separate and Store. Each step requires a different action to increase efficiency. You can make it easy for people to find things later by sorting them. When items are ordered, they are put together. You then organize your inventory in groups. Make sure everything is correctly labeled when you label your containers.

Employees need to reflect on how they do their jobs. Employees must understand why they do certain tasks and decide if there's another way to accomplish them without relying on the old ways of doing things. They will need to develop new skills and techniques in order for the 5S system to be implemented.

The 5S method not only increases efficiency but also boosts morale and teamwork. Once they start to notice improvements, they are motivated to keep working towards their goal of increasing efficiency.