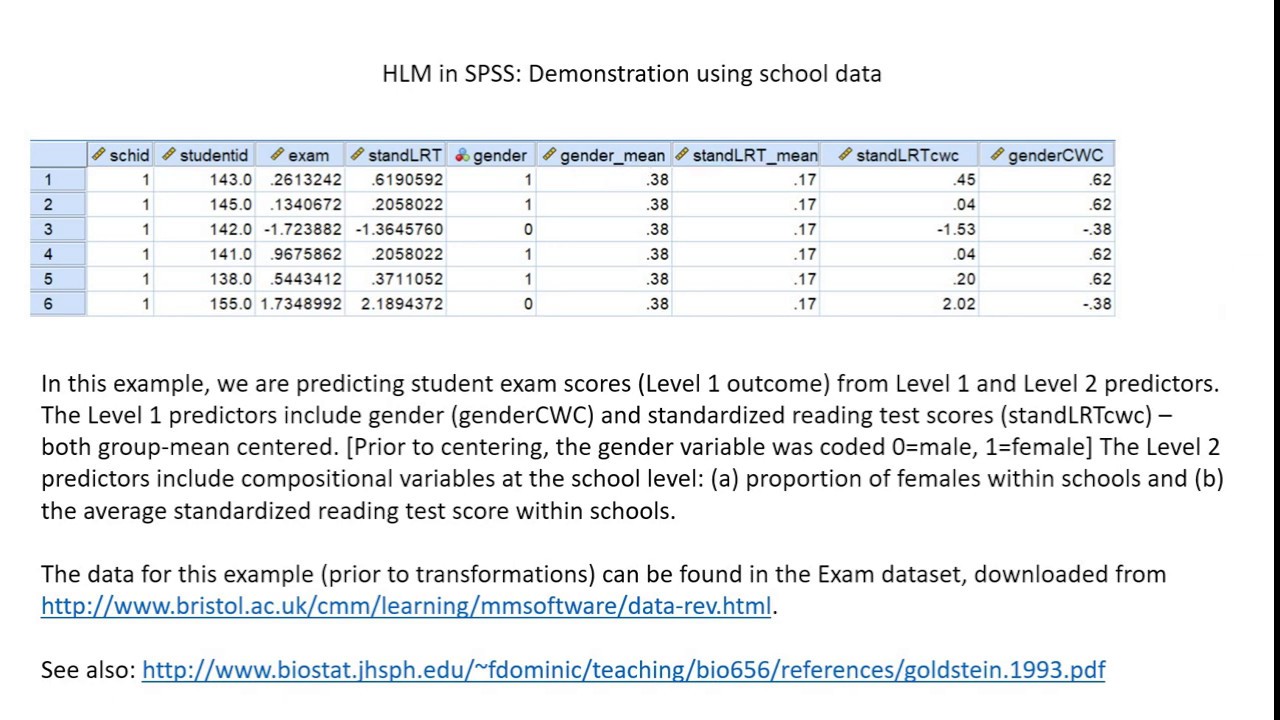

SIPOC diagrams are a helpful visual tool for defining the inputs, outputs, and business processes. This tool allows members of a team to identify areas for improvement or any gaps that exist in the operations.

The sipoc diagram can often be found in the DMAIC cycle of process improvement, a framework that is used to create a business process which can be improved by analysis and continual improvement. It can also help teams and sponsors reach agreement on project boundaries, scope, and Key Process Input Variables.

What is SIPOC and what does it do?

The SIPOC Diagram is a simple, easy-to understand visual representation of inputs and out-puts for a particular business process. Its primary goal is to help the team analyze and understand the business process on a high-level, by providing a clear image of the steps needed to convert inputs into outputs.

What is history of sipoc diagrams?

The sipoc chart can be traced to the late 80s. It was developed as part of total quality (TQM) and Six Sigma models for improving business processes. Since then, its use in lean manufacturing programs and business process improvements has expanded. It is a valuable tool for streamlining and identifying processes and potential improvements.

How to Make a SIPOC?

In order to construct a SIPOC chart, the first thing you need to do is choose which business process you would like to analyze. This will ensure that you and your staff focus on only the most important aspects and don't miss any details.

Next, you will need to identify all the inputs needed for the process. This includes who supplies these inputs. You should list each supplier and their contact information, along with the raw materials that they provide to the process.

List all clients, internal and outside, who will receive the product or service. This can help to ensure that the company is providing high-quality products and services.

Inputs is the first part of the SIPOC diagram. It contains the specifications for the materials or information that the process requires. The material can be physical goods, such as a product, or information, such as a report.

Outputs: This is the second section of a SIPOC diagram and is typically a list of products, services, or completed actions that are produced as a result of the process. The outputs need to reflect the value the customer expects from the process and meet their needs.

Customers: This section is the last of a SIPOC Diagram and it identifies all the clients who will receive the outputs from the process, internal or external to the organisation. This includes the maintenance team as well as line operators and other internal or external clients.

SIPOC diagrams are a powerful tool to improve communication and business processes. It is simple to create and a good way to ensure that team members are aware of the business processes under consideration. It's best to use templates that include all key diagram components such as inputs or outputs. It can save you time as well as effort by using a pre-made template.

FAQ

What are the 7 Rs of logistics?

The acronym "7R's" of Logistics stands for seven principles that underpin logistics management. It was published in 2004 by the International Association of Business Logisticians as part of their "Seven Principles of Logistics Management" series.

The following letters form the acronym:

-

Responsible – ensure that all actions are legal and don't cause harm to anyone else.

-

Reliable – have faith in your ability and capability to keep promises.

-

Reasonable - use resources efficiently and don't waste them.

-

Realistic - Consider all aspects of operations, including environmental impact and cost effectiveness.

-

Respectful - show respect and treat others fairly and fairly

-

Reliable - Find ways to save money and increase your productivity.

-

Recognizable provides value-added products and services to customers

What makes a production planner different from a project manger?

The primary difference between a producer planner and a manager of a project is that the manager usually plans and organizes the whole project, while a production planner is only involved in the planning stage.

How can I learn about manufacturing?

Experience is the best way for you to learn about manufacturing. You can read books, or watch instructional videos if you don't have the opportunity to do so.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to use 5S to increase Productivity in Manufacturing

5S stands in for "Sort", the "Set In Order", "Standardize", or "Separate". Toyota Motor Corporation was the first to develop the 5S approach in 1954. It allows companies to improve their work environment, thereby achieving greater efficiency.

This method has the basic goal of standardizing production processes to make them repeatable. This means that tasks such as cleaning, sorting, storing, packing, and labeling are performed daily. Because workers know what they can expect, this helps them perform their jobs more efficiently.

There are five steps that you need to follow in order to implement 5S. Each step involves a different action which leads to increased efficiency. You can make it easy for people to find things later by sorting them. Once you have placed items in an ordered fashion, you will put them together. You then organize your inventory in groups. You can also label your containers to ensure everything is properly labeled.

Employees will need to be more critical about their work. Employees need to be able understand their motivations and discover alternative ways to do them. They must learn new skills and techniques in order to implement the 5S system.

In addition to increasing efficiency, the 5S method also improves morale and teamwork among employees. As they begin to see improvements, they feel motivated to continue working towards the goal of achieving higher levels of efficiency.