When looking at the economics of consumer goods, there are two categories: durable goods and non-durable goods. Durable goods are durable and last a long time. Non-durable products have a shorter lifecycle and need to be replaced more often.

Cars and clothes are examples of durable goods that last a very long time. Durable goods can be more expensive because they last longer and are less likely to wear out.

This distinction between durable and non-durable goods is important for economists and investors alike, because it can provide a quick and easy way to understand the economy. During an expanding economy, both households and businesses will be more inclined to purchase durable products, whereas during a downturn, they are less likely to do so.

The durable good report is an economic indicator which provides insight into the U.S. Manufacturing sector and economy in general.

When the volume of durable goods orders increases, it indicates that the manufacturing industry is healthy and expects growth in the future. Manufacturers are likely to hire workers, which can help to strengthen the overall economy. If, on the other hand the durable good orders report is decreasing, then manufacturers are less optimistic about the economy.

A durable item is a tangible object that doesn't easily break down, wear out or rot. It doesn't need to be replaced as often and it is used several times before its utility fades away.

Appliances, clothing, computer, furniture, and even cars are examples of durable goods. These durable goods can be used repeatedly before they begin to degrade.

The economy is influenced by the expenditures on durable goods. They show that businesses and individuals are anticipating an economic recovery, and are therefore willing to buy products and services which will positively impact their lives.

They also contribute to increasing employment, which in turn can lead to increased productivity and reduced costs over the long term. In addition, investments in durable goods can be beneficial to the environment because they're less wasteful than non-durables.

The durable good orders report measures the demand for U.S. manufactured durable goods both nationally and internationally. It is published monthly by the United States Census Bureau.

Durable goods orders are used by economists and investors to gauge the state of the economy. The durable goods order report indicates that consumers want to buy products and services which will last for more than three years.

When durable goods orders decline, it shows that consumers do not want to purchase products or services lasting less than 3 years.

The durable goods reports is a report which measures the monthly demand for durables goods. Durable goods are those items that can last over three years. It's an important indicator because it shows how the economy is doing.

FAQ

What are the 7 Rs of logistics.

The acronym 7R's for Logistics stands to represent the seven basic principles in logistics management. It was developed by International Association of Business Logisticians (IABL), and published as part of their "Seven Principles of Logistics Management Series" in 2004.

The acronym consists of the following letters:

-

Responsible - ensure that actions are in compliance with legal requirements and do not cause harm to others.

-

Reliable - Have confidence in your ability to fulfill all of your commitments.

-

Use resources effectively and sparingly.

-

Realistic - Take into consideration all aspects of operations including cost-effectiveness, environmental impact, and other factors.

-

Respectful - show respect and treat others fairly and fairly

-

You are resourceful and look for ways to save money while increasing productivity.

-

Recognizable: Provide customers with value-added service

What is the responsibility of a manufacturing manager?

Manufacturing managers must ensure that manufacturing processes are efficient, effective, and cost-effective. They should be alert for any potential problems in the company and react accordingly.

They must also be able to communicate with sales and marketing departments.

They should be informed about industry trends and be able make use of this information to improve their productivity and efficiency.

How can manufacturing prevent production bottlenecks?

Avoiding production bottlenecks is as simple as keeping all processes running smoothly, from the time an order is received until the product ships.

This includes planning for both capacity requirements and quality control measures.

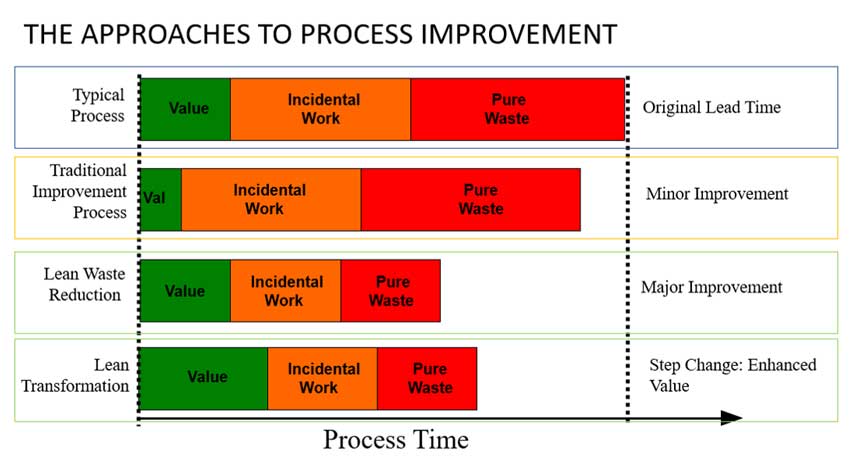

Continuous improvement techniques such Six Sigma can help you achieve this.

Six Sigma management is a system that improves quality and reduces waste within your organization.

It focuses on eliminating variation and creating consistency in your work.

What does manufacturing mean?

Manufacturing Industries is a group of businesses that produce goods for sale. The people who buy these products are called consumers. This is accomplished by using a variety of processes, including production, distribution and retailing. They produce goods from raw materials by using machines and other machinery. This includes all types manufactured goods such as clothing, building materials, furniture, electronics, tools and machinery.

What is it like to manage a logistics company?

A successful logistics business requires a lot more than just knowledge. You must have good communication skills to interact effectively with your clients and suppliers. You must be able analyze data and draw out conclusions. You must be able and able to handle stress situations and work under pressure. You must be creative and innovative to develop new ideas to improve efficiency. You must be a strong leader to motivate others and direct them to achieve organizational goals.

To meet tight deadlines, you must also be efficient and organized.

How can efficiency in manufacturing be improved?

The first step is to determine the key factors that impact production time. We then need to figure out how to improve these variables. If you aren't sure where to begin, think about the factors that have the greatest impact on production time. Once you've identified them all, find solutions to each one.

Statistics

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

Six Sigma: How to Use it in Manufacturing

Six Sigma can be described as "the use of statistical process control (SPC), techniques to achieve continuous improvement." Motorola's Quality Improvement Department created Six Sigma at their Tokyo plant, Japan in 1986. Six Sigma is a method to improve quality through standardization and elimination of defects. Since there are no perfect products, or services, this approach has been adopted by many companies over the years. Six Sigma's primary goal is to reduce variation from the average value of production. You can calculate the percentage of deviation from the norm by taking a sample of your product and comparing it to the average. If there is a significant deviation from the norm, you will know that something needs to change.

Understanding how your business' variability is a key step towards Six Sigma implementation is the first. Once you understand this, you can then identify the causes of variation. You'll also want to determine whether these variations are random or systematic. Random variations are caused when people make mistakes. While systematic variations are caused outside of the process, they can occur. For example, if you're making widgets, and some of them fall off the assembly line, those would be considered random variations. However, if you notice that every time you assemble a widget, it always falls apart at exactly the same place, then that would be a systematic problem.

Once you identify the problem areas, it is time to create solutions. It might mean changing the way you do business or redesigning it entirely. After implementing the new changes, you should test them again to see if they worked. If they fail, you can go back to the drawing board to come up with a different plan.