Global supply-chain management is the process of distributing goods and services within a global company's network. The idea is to maximize profit and minimize waste. This distribution method offers many benefits, but there are some downsides. Let's look at some of these issues. Read on to learn more about the benefits of global supply chain management. We will also address some of the problems associated with global supply chain management.

Resilience

An effective global supply manager must have a strategy to promote resilience. Designing and redundancies in the supply network can help increase the supply's resilience. While supply chains are rigid in the short term, they can be resilient with creativity, innovation, and constant vigilance. Cin7 is one inventory management software provider that offers various educational materials.

Information sharing

Although information sharing is not a well-known concept in global supply chain management it is critical to the survival, growth and success of enterprises. This study examines information sharing and how it can benefit different parties in a supply-chain. Information sharing offers many benefits, which may vary depending on the type of information. In general, the value of information varies depending on the parties involved. Below are examples of information that may benefit supply chains.

Quality management

Quality issues are a critical part of any supply network. It is crucial for companies to ensure product quality. However it is equally important that secondary issues are addressed and supply chain risk managed. This article will cover the role and importance of quality management for global supply chain management. It will also highlight how existing business systems can fail to meet this challenge. Let's examine how companies can overcome these obstacles and implement quality management strategies that are more efficient.

Logistics links

As consumers' demands and preferences continue to evolve, so do the needs of the business. The global supply chain is a complex web of suppliers, individuals, and companies that works together to deliver goods on time and to the right place. Logistics plays a vital role in global logistics management. It allows companies to lower their costs while improving their performance. Supply chains encompass vendors, suppliers, producers, warehouses and transportation companies as well as retailers.

Pandemic COVID-19

Global supply chain management is urgently needed due to the large-scale spread of COVID-19. To respond to emergencies, global supply chains are critical. They ensure that essential supplies are available in a timely manner. Other issues have strained the global supply chains, such as China's ongoing lockdown and economic uncertainty. This pandemic is proving to be a test of supply chain resilience and flexibility. Companies will be judged on not only their response but also their corporate values after this crisis.

Impact on the economy

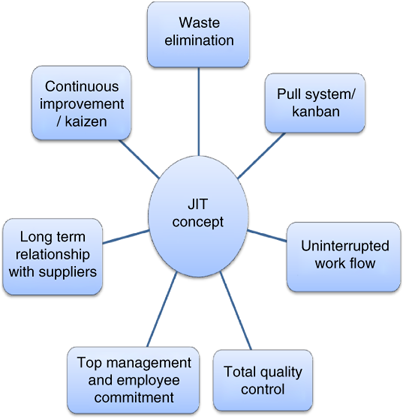

Global supply chain management plays a vital role in the global economy. As more manufacturers shift to JIT production (just-in time), they become increasingly dependent upon a single source of vital supplies. However, JIT production models have a large drawback: they make companies vulnerable to disruptions in their supply chains. Recent research has shown that half of the executives plan to cut production from China and that one-third plan on de-emphasizing JIT manufacturing.

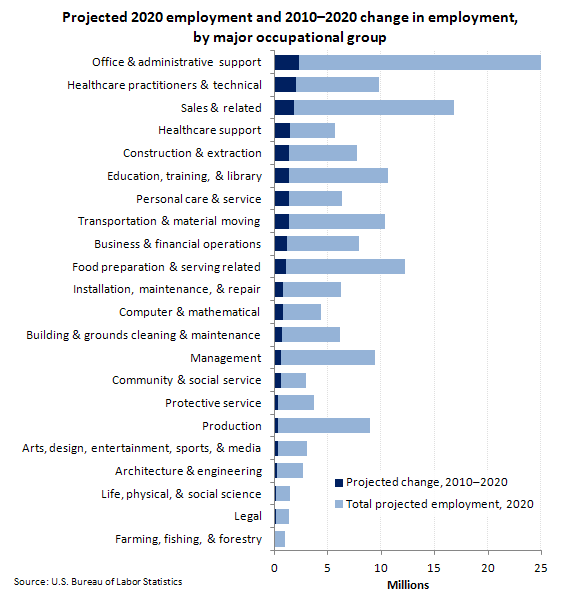

Opportunities for career advancement

Global supply chain management oversees all aspects of an organization's international procurement strategy. They manage inventory logistics and work with suppliers to ensure top-quality products. They keep track of the supply chain performance, analyze data and make recommendations. This role also requires a great deal of collaboration with other departments in a company. These are just a few career options that people with this type of background can choose from. All of them provide valuable career benefits.

FAQ

What is the job of a logistics manger?

Logistics managers are responsible for ensuring that all goods arrive in perfect condition and on time. This is done through his/her expertise and knowledge about the company's product range. He/she must also ensure sufficient stock to meet the demand.

Why is logistics so important in manufacturing?

Logistics are an integral part any business. They help you achieve great results by helping you manage all aspects of product flow, from raw materials to finished goods.

Logistics play an important role in reducing costs as well as increasing efficiency.

What do you mean by warehouse?

A warehouse is a place where goods are stored until they are sold. It can be an indoor space or an outdoor area. In some cases, it may be a combination of both.

Can we automate some parts of manufacturing?

Yes! Automation has been around since ancient times. The Egyptians invented the wheel thousands of years ago. Robots are now used to assist us in assembly lines.

Actually, robotics can be used in manufacturing for many purposes. These include:

-

Line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Manufacturing can also be automated in many other ways. For instance, 3D printing allows us make custom products and not have to wait for months or even weeks to get them made.

What skills should a production planner have?

Being a production planner is not easy. You need to be organized and flexible. Effective communication with clients and colleagues is essential.

What are the 7 Rs of logistics management?

The acronym 7R's for Logistics stands to represent the seven basic principles in logistics management. It was developed by International Association of Business Logisticians (IABL), and published as part of their "Seven Principles of Logistics Management Series" in 2004.

The acronym consists of the following letters:

-

Responsive - ensure all actions are legal and not harmful to others.

-

Reliable: Have faith in your ability or the ability to honor any promises made.

-

Reasonable - make sure you use your resources well and don't waste them.

-

Realistic – consider all aspects of operations, from cost-effectiveness to environmental impact.

-

Respectful - treat people fairly and equitably.

-

Be resourceful: Look for opportunities to save money or increase productivity.

-

Recognizable - Provide value-added services to customers

What can I do to learn more about manufacturing?

The best way to learn about manufacturing is through hands-on experience. You can read books, or watch instructional videos if you don't have the opportunity to do so.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

Six Sigma in Manufacturing

Six Sigma is "the application statistical process control (SPC), techniques for continuous improvement." It was developed by Motorola's Quality Improvement Department at their plant in Tokyo, Japan, in 1986. Six Sigma's basic concept is to improve quality and eliminate defects through standardization. This method has been adopted by many companies in recent years as they believe there are no perfect products or services. The main goal of Six Sigma is to reduce variation from the mean value of production. This means that you can take a sample from your product and then compare its performance to the average to find out how often the process differs from the norm. If it is too large, it means that there are problems.

Understanding how your business' variability is a key step towards Six Sigma implementation is the first. Once you understand this, you can then identify the causes of variation. It is important to identify whether the variations are random or systemic. Random variations are caused by human errors. Systematic variations can be caused by outside factors. For example, if you're making widgets, and some of them fall off the assembly line, those would be considered random variations. If however, you notice that each time you assemble a widget it falls apart in exactly the same spot, that is a problem.

Once you identify the problem areas, it is time to create solutions. You might need to change the way you work or completely redesign the process. You should then test the changes again after they have been implemented. If they fail, you can go back to the drawing board to come up with a different plan.